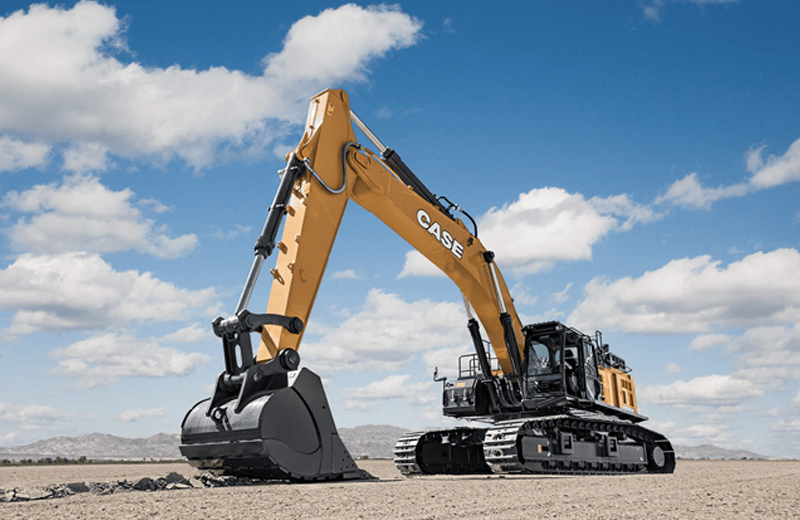

Boost Your Construction Projects with Premium Aftermarket Construction Parts Selection

Wiki Article

Boost Performance With Aftermarket Components: a Guide for Heavy Equipment Owners

Advantages of Aftermarket Components

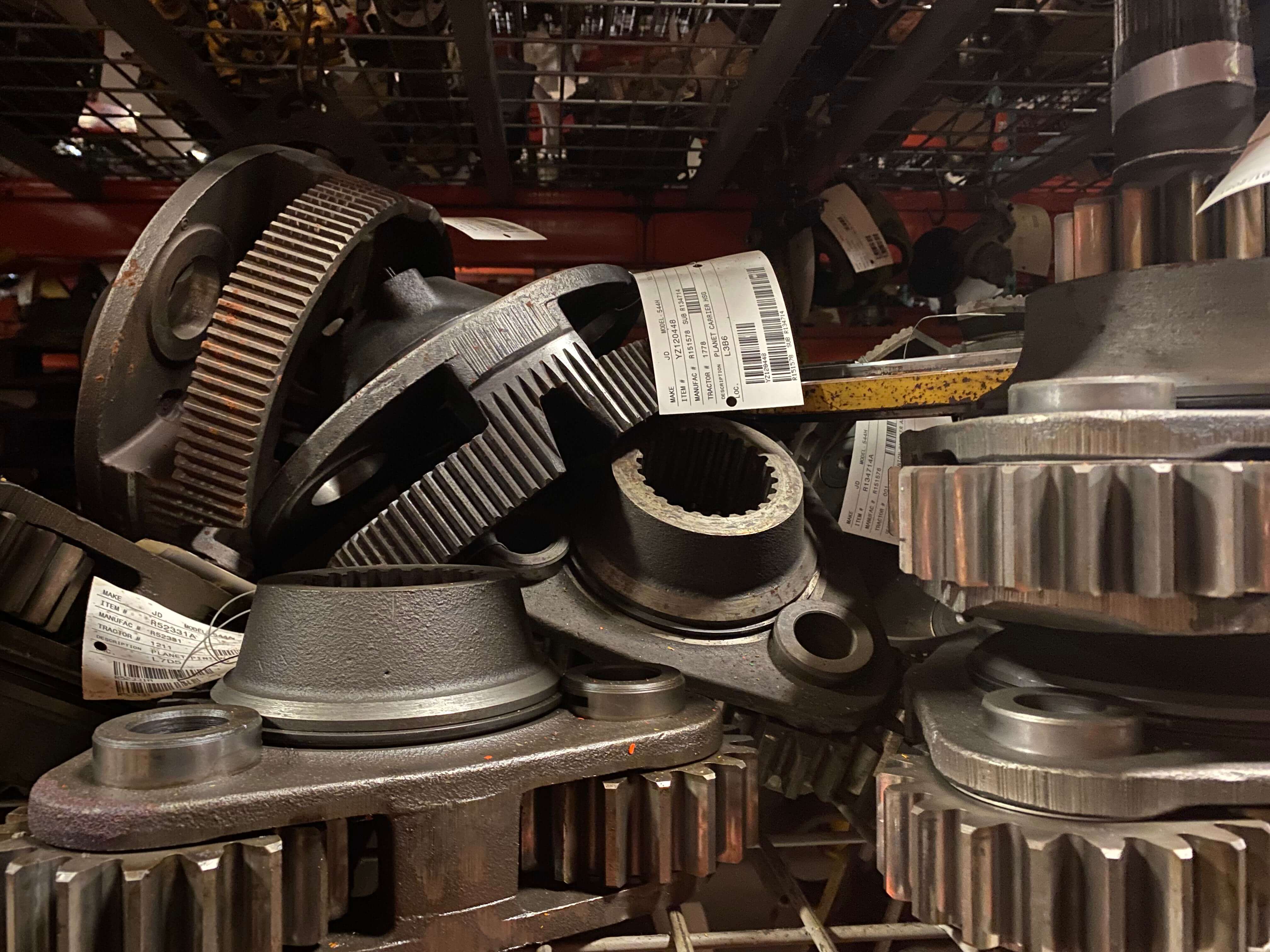

Owners of heavy equipment can delight in countless benefits by deciding for aftermarket parts over original equipment maker (OEM) parts. Aftermarket parts are typically a lot more economical than OEM components, permitting equipment proprietors to reduce upkeep and fixing costs without endangering on high quality.Considering that aftermarket makers specialize in generating specific parts, equipment proprietors have accessibility to a more comprehensive range of choices to suit their needs. Aftermarket components are recognized for their top quality and dependability, with numerous meeting or exceeding OEM standards.

Last but not least, selecting aftermarket parts can also lead to faster fixings and minimized downtime. With simpler availability and fast delivery choices, machinery proprietors can obtain their equipment up and running once more quickly, reducing disruptions to their procedures.

Selecting the Right Aftermarket Parts

When taking into consideration aftermarket parts for hefty machinery, it is vital to focus on compatibility and high quality to ensure optimum performance and long life of the devices. Picking the best aftermarket components can be an important decision for hefty machinery proprietors as it straight affects the performance and dependability of their tools.

Second of all, quality should never be jeopardized when selecting aftermarket components (aftermarket construction parts). Selecting top quality elements makes certain durability, reliability, and overall performance of the machinery. It is recommended to resource aftermarket parts from respectable makers or distributors recognized for their top quality criteria

Additionally, considering elements such as warranties, customer testimonials, and compatibility with existing systems can better assist in making the appropriate selection. By focusing on compatibility and high quality when choosing aftermarket parts, hefty equipment owners can improve the efficiency and longevity of their tools.

Setup and Maintenance Tips

For reliable procedure and long life of heavy machinery, correct installation and regular maintenance are extremely important. When setting up aftermarket components, ensure that you carefully comply with the supplier's instructions to ensure optimum performance. It is important to use the proper devices and techniques to stop any kind of damage during the setup procedure. Regular maintenance is important to maintain your equipment running efficiently. Develop a maintenance routine that consists of jobs such as checking fluid levels, examining for deterioration, and cleaning elements (aftermarket construction parts). Immediately resolve any kind of issues that arise to avoid additional damage and costly repairs. Additionally, consider investing in training for your maintenance staff to ensure they have the necessary skills to identify and address potential troubles. By focusing on installment and upkeep treatments, you can make the most of the efficiency i loved this and lifespan of your hefty equipment, eventually saving time and cash in the long run.

Cost-Effectiveness of Aftermarket Components

Appropriate installation and regular upkeep are fundamental elements for heavy equipment owners aiming to analyze the cost-effectiveness of aftermarket components for their equipment. While initial devices producer (OEM) components are recognized for their quality, aftermarket components use a more directory cost-efficient solution without endangering performance. By carefully examining the quality and compatibility of aftermarket components with their machinery, proprietors can strike a balance between cost-effectiveness and efficiency, ultimately making best use of the effectiveness and long life of their heavy tools.Optimizing Efficiency With Aftermarket Upgrades

To improve functional performance and productivity, heavy machinery owners can successfully optimize efficiency with critical usage of aftermarket upgrades. Aftermarket upgrades supply the opportunity to customize hefty machinery to certain functional needs, leading to boosted functionality and result. Updating elements such as engines, transmissions, hydraulic systems, and tracks can dramatically enhance the general effectiveness of the equipment.

Routinely assessing the efficiency of heavy equipment and identifying locations where aftermarket upgrades can be beneficial is necessary for maximizing performance. By investing in quality aftermarket components and upgrades, equipment owners can attain higher degrees of efficiency, eventually resulting in set you back savings and enhanced functional outcomes.

Final Thought

In conclusion, aftermarket parts supply various advantages for hefty machinery proprietors, consisting of cost-effectiveness, enhanced effectiveness, and customization options. By selecting the appropriate aftermarket parts, complying with correct installation and maintenance procedures, and making best use of upgrades, hefty machinery owners can improve their tools's performance and longevity. Purchasing aftermarket parts can eventually bring about improved efficiency and minimized downtime, making it a rewarding consideration for owners wanting to enhance their machinery operations.Owners of heavy machinery can take pleasure in countless advantages by deciding for aftermarket components over initial tools supplier (OEM) components. Aftermarket components are usually extra economical than OEM parts, enabling machinery owners to lower upkeep and fixing prices without endangering on top quality. By meticulously reviewing the top quality and compatibility of aftermarket components with their machinery, proprietors can strike an equilibrium in between cost-effectiveness and performance, ultimately taking full advantage of the efficiency and longevity of their hefty devices.

In conclusion, aftermarket parts supply countless benefits for heavy equipment owners, including cost-effectiveness, increased performance, and customization alternatives. By picking the best aftermarket parts, adhering to proper installation and upkeep procedures, and making the most of upgrades, hefty visit site machinery proprietors can boost their equipment's efficiency and long life.

Report this wiki page